with Increasing Trends

Mechanical Works

Mechanical technology is the core of industrialization and Solustrid provides the best solution for any kind.

Automation Industry

Automation is the topmost technology in today’s world and we are the topper at it. We have already provided.

Petrolium Refinery

We refine Petroliums in the best possible way that our customers can have the cent percent use of it.We guarantee.

Industry Construction

Industrial construction is a specific form of building that requires expert training and highly experienced.

We Are The Leading Industrial

Factory In The World

Steeler was created in 2014 to secure U.S. global leadership in manufacturing by connecting people, ideas, and technology. Manufacturing USA institutes convene business competitors, academic institutions, and other stakeholders.

Create new products, reduce cost and risk, and enable the manufacturing. Innovations enabled by the Steeler institutes results in products that assist workers, make buildings safer, consume less energy. There are many variations of passages of Lorem Ipsum available but the majority have suffered that a alteration in that some form by injected .

Harry Oliver,

CEO of Steeler Industrial

Our Latest Projects

technology, R&D, etc. are integrated to give a complete solutions package.

Find Out More About Us

Društvo Ćosićpromex d.o.o. je ulaganjem u izgradnju vlastite proizvodne hale pokrenulo novi smjer u svom poslovanju. Okrenuli su se proizvodnji konstrukcija i dijelova od metala, potaknuti idejom da je proizvodnja osnovni pokretač ekonomije i društva u kojem živimo.

Poslovanjem u metalnom sektoru koje traje više od 20 godina etabllirali smo se u industiji čelika kao pouzdan i kvalitetan partner što potvrđuje podatak da je 95% proizvodnje izvozno orjenitrano.

Sa ciljem ispunjavanja strogih europskih zahtjeva na kvalitet konstntantno je ulaganja u osovuremenjivanje proizvodnih kapaciteta i praćenje najonvihih trendova u oblasti metalnog sektora. Pa su iz tog razloga izgradili dvije proizvodne hale ukupne površine 5500 m2 sa reguliranim pristupom za logistiku, građenu po najvišim standardima i potrebama današnjeg modernog proizvodnog pogona, nabavkom najsuvremenijih aparta za zavarivanje i CNC plazma rezačice radnih dimenzija 2500 mm x 6000 mm maksimalne debljine rezanja čelika debljine do 120 mm.

Također je u tijeku i izgradnja treće proizvodne hale ukupne površine 2750 m2.

U pogonima Ćosićpromex-a sljedeće su usluge iz djelatnosti obrade metala:

- Izrada i ugradnja metalnih konstrukcija

- Rezanje metala plazmom

- Usluge zavarivanja: REL, MIG/MAG, TIG i plinsko

- Kutno savijanje metala

- Pjeskarenje i farbanje metala

- Montaža – remont plinskih i cjevovodnih instalacija

- Izrada i montaža ventilacijskih sustava

- Montaža termotehničkih instalacija

- Bravarski radovi

- Izrada i ugradnja ograda i kapija od CrNi (inox) čelika

- Izgradnja hidrotehničkih objekata

- Izrada i montaža građevinske limarije

- Izolacioni radovi

Gore navedene usluge izvode educirani djelatnici predvođeni i nadzirani inžinjerima strojarstva i inženjerima zavarivanja (IWE), a sve prema Tüv ISO 9001 i ISO 14001 standardu upravljanja kvalitetom i zaštitom okoliša te prema DIN EN 1090-1,2 i EN ISO 3834-2+PED+AD2000 standardima za zavarivanje, izvođenje čeličnih konstrukcija i posuda pod tlakom.

Za potrebe izvođenja usluga nabavili su vrhunske strojeve, alate i prateću opremu, a stalnim rastom proizvodnje ulažu u nabavku nove opreme, prateći zahtjeve tržišta i razvoj novih tehnologija.

OUR MISSION

As a provider for complex steel structures, we can procure, manufacture and assemble tailor made solutions. Customers approach us because they know that we can handle and machine. assemble tailor made components and solutions driving.

OUR VISION

Our vision is to be the preferred supplier to our customers and, by being preferred supplier, to improve their competitive power. We strive to become and to remain the preferred supplier to all our customers, because this is how we can identify.

1955 - From Birth to a Period of Growth

Nippon Gakki Hamana Factory established in Hamakita-cho (present Hamamatsu city), Hamana-gun, Shizuoka Pref and production of our first product, the 125cc Yamaha motorcycle “YA-1” begins.

1970 - Creation of Demand and New Business

Yamaha Motor Canada Limited (YMCA) founded in Canada. Signed joint venture agreement with Brunswick Co. (U.S.) and Brunswick invests in Sanshin Industries.

2000 - Opening up Limitless Worlds of Potential

Yamaha builds temporary pool “Suimu 21” for the main competition pool of the 9th World Swimming Championships in Fukuoka, Japan Yamaha succeeds in the high-concentration mass culturing.

2010 - Moving further with global operations and monozukuri reforms

Medium-term management plan with central pillars of structural reform and growth strategies announced. Start of increased manufactuaring of Japanese boats to assist Great East Japan Earthquake recovery efforts.

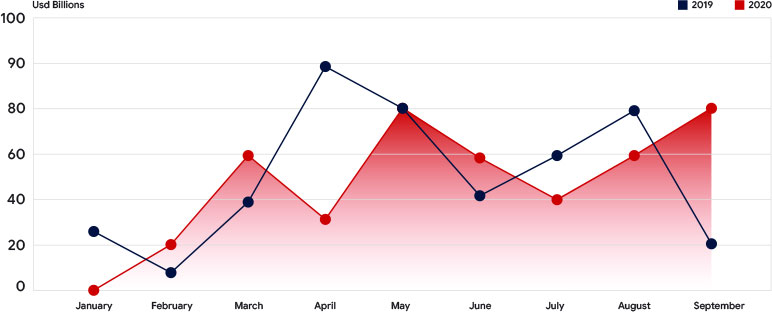

Refer to the statistics of our company. Manufacturer’s high end manufacturing services are a perfect complement to today’s high tech industries.

1

Years Experience

1 +

happy customer

1

distributor

1

factory industrial

Testimonials

“ During the time I have worked with SCG on this project, I have found Mike Campbell and his team to be highly knowledgeable and results-driven. Based on preliminary pilot testing and a strong understanding of subsurface. conditions, in particular fractured bedrock environments. ased on their work on this project. "

Derek AuCoin

Defence Construction Canada

“ For over 10 years working with SCG Industries on environmental contaminated sites they have continuously demonstrated excellent technical ability while ensuring superior customer service. Their collaborative approach and real time flexibility in adapting to changing conditions has contributed to the success of many project goals. “

Derek AuCoin

Defence Construction Canada

“ For over 10 years working with SCG Industries on environmental contaminated sites they have continuously demonstrated excellent technical ability while ensuring superior customer service. Their collaborative approach and real time flexibility in adapting to changing conditions has contributed to the success of many project goals. “

Derek AuCoin

Defence Construction Canada

“ For over 10 years working with SCG Industries on environmental contaminated sites they have continuously demonstrated excellent technical ability while ensuring superior customer service. Their collaborative approach and real time flexibility in adapting to changing conditions has contributed to the success of many project goals. “

Derek AuCoin

Defence Construction Canada

Our Teams

William Charles

Anthony Jeffrey

Stephen Scott

David Nelson

Boston Lynch

DELIVERING INNOVATION

Sustainability Goals

We are focused on building a long-term, sustainable business.